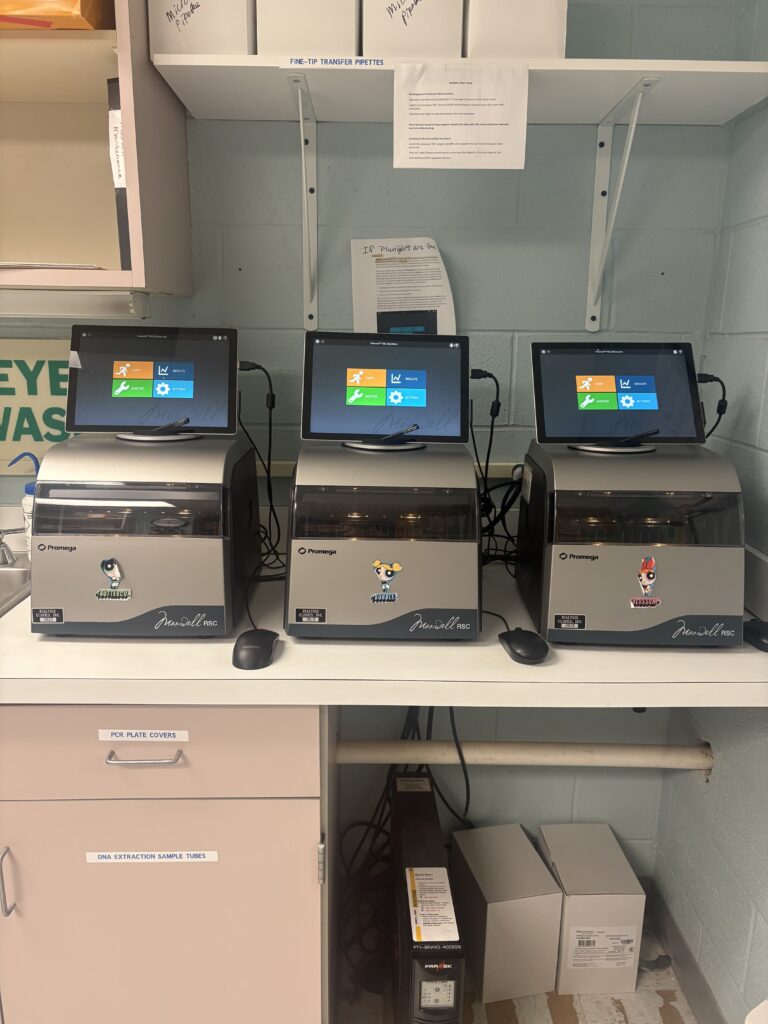

For twenty years, the transplant lab at Dialysis Clinic, Inc. (DCi) in Nashville, TN has depended on Maxwell instruments for their automated nucleic acid purification. In fact, the lab was the first to purchase the instrument when it debuted in 2005. Today, they’ve scaled up to three of the latest Maxwell® Instruments.

“They’re great little instruments,” says Christina Sholar, Clinical Supervisor at DCi. “I think this is our third generation, and we still have the original in the basement. We love them.”

Christina’s lab runs critical tests to ensure compatibility between donors and recipients for solid organ and stem cell transplants. With precious samples and urgent demands, they need tools they can depend on for high-quality results. Their Maxwell® instruments help them ensure successful downstream analysis to support important clinical decisions.

Precious Samples, Urgent Timelines

Founded in 1971 as a non-profit dialysis clinic, DCi now supports a broad spectrum of kidney health issues, including transplants. The company has also expanded its operations to support organ transplants through federally designated organ procurement organizations. Christina’s lab runs the tests to ensure compatibility between donors and recipients.

“We cover the state of Tennessee,” Christina says. “We do the typing and antibody analysis for solid organ transplants, and then we follow them post-transplant to see if they’ve developed antibodies to the donor. We also do stem cell workups and follow-ups.”

The lab processes 150-200 samples per week. In addition to managing the high sample throughput, the team also must be available 24/7 for urgent calls when an organ donor passes away.

“We used to average about 50 donors a month, but that’s creeping up,” Christina says.

Christina says her team needs a workflow built for speed and minimal hands-on processing. With downstream assays including NGS and qPCR, they also need to trust they’ll have a high-quality DNA sample to work with. That’s what led them to the Maxwell platform in 2005.

Instrumentation for Easy, Reliable Results

“Maxwell purifications are an easy thing to start new employees with, because they can get quality DNA very easily,” says MacKenzie Gartner, Lead Technologist in Christina’s lab at DCi. “Techs pick up on it very quickly, and it’s something they can feel confident in doing by themselves.”

Twenty years ago, the lab was using manual methods to purify all their nucleic acids. Unlike MacKenzie, Christina remembers those days and admits they weren’t fun. The protocols were labor-intensive, and much more prone to human error. Now, they don’t even teach manual methods anymore.

“When I came on nine years ago, they were teaching a manual method as backup for the Maxwell instruments, but they never got around teaching it to me because it was needed so rarely,” MacKenzie says. “Now it’s not even in the training materials.”

MacKenzie works hands-on with the Maxwell instruments almost every day. The lab mainly uses the Maxwell® Buffy Coat DNA Kit and Maxwell® Buccal Swab DNA Kit. Buccal swabs require 20 minutes of passive pre-processing, but buffy coats can be added directly to the Maxwell cartridges. From there, the automated protocol is only 45 minutes.

“It’s nice that both of them can be run on the same instrument, which gives us flexibility knowing that all three instruments can be available no matter what we’re doing,” MacKenzie adds.

Christina says the Maxwell instruments provide much cleaner DNA eluates than their past manual methods. This is invaluable for lab efficiency, but it’s even more important with stem cell testing.

“With stem cells, they may only send one tube but want three or four different tests,” she explains. “We don’t have room for error – those samples are precious.”

“We keep the instruments pretty active,” MacKenzie adds. “That room constantly has their little noises going. But they’re so dependable – they don’t take much maintenance, and we can count on having one available even when we get some urgent samples from a donor.”

Long-Term Partnership for Success

“Promega is probably our favorite company to work with, as far as support goes,” Christina says. “We rarely have issues, but when we do, we get great responses very quickly.”

As a leader, Christina values strong relationships with her suppliers. Though the lab’s sales representative has changed a few times over the past two decades, she says each one has been reliable and helpful in keeping the lab operations running smoothly. The lab has also benefited from regularly scheduled preventive maintenance visits from Promega service engineers.

“Overall, I just love how dependable the instruments are,” Christina says. “We’re using them all the time. They’re truly our workhorses.”

All photos credit: DCi