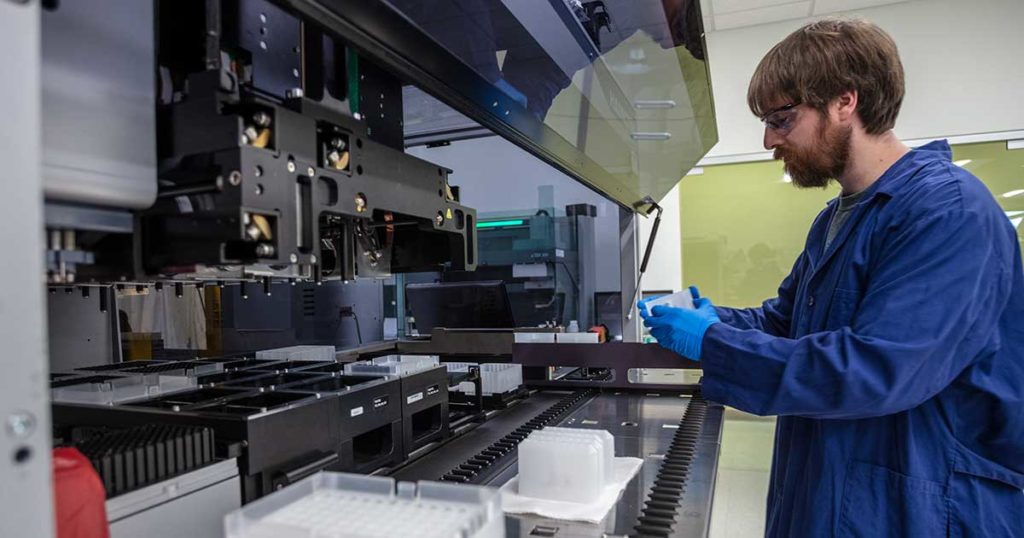

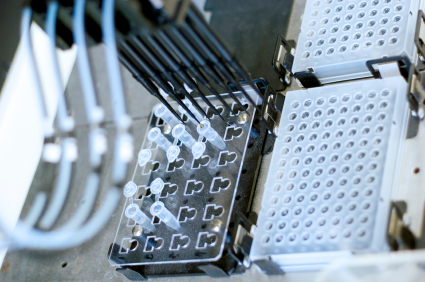

In the summer of 2000, Promega research scientist Allan Tereba was asked to develop an automated protocol for purifying DNA for forensics. His team had recently launched DNA IQ, the first Promega kit for purifying forensic DNA using magnetic beads. This was before the Maxwell® instruments, and before Promega purification chemistries were widely adaptable to high-throughput automation.

“I had my doubts about being able to do that,” Allan says. “When you’re working with STRs, small amounts of contaminant DNA are going to mess up your results. But I went ahead and tried it, and it was a challenge.”

A little over a year later, Allan was in his office when he heard on the radio that a plane had struck the North tower of the World Trade Center in New York City. Shortly after, he heard the announcement that a second plane had hit the South tower.

By that point, Allan and his colleagues had successfully adapted DNA IQ to be used on the deck of a robot. Within days of the attacks, Promega scientists were supporting the New York City Office of Chief Medical Examiner (OCME) and New York State Police in their work to identify human remains that were recovered from Ground Zero.

Thanks to the work of Allan and many other Promega scientists, Promega was prepared to offer unique solutions to urgent needs. In their own words, here are some of those scientists’ reflections.

Continue reading “Automating Forensic DNA Purification to Meet Urgent Needs: Reflections on September 11, 2001”