This review is a guest blog by Amy Landreman, Product Specialist in Cellular Analysis at Promega Corporation.

This review is a guest blog by Amy Landreman, Product Specialist in Cellular Analysis at Promega Corporation.

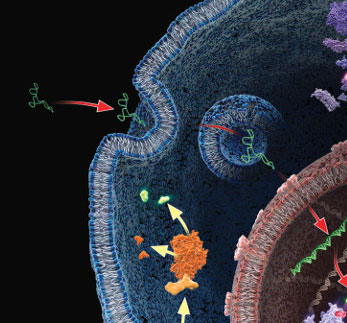

Lentiviral vectors (LVV) have become a valuable research tool for delivering genetic content into a wide range of cell types. Commonly derived from the HIV-1 genome, LVV have the advantage of being able to infect both dividing and non-dividing cells. They can be particularly valuable for introducing genetic material into cell lines that are difficult to transfect using other methods and are also being used in gene therapy applications.

Unlike other gene delivery tools, transducing mammalian cells with LVV requires significant upfront effort since the LVV particles carrying the desired genetic content first need to be created. In general this involves co-transfecting a packaging cell line, such as HEK293T, with a set of three to four separate plasmids that encode the protein content required to generate the LVV particles: the transfer plasmid, which contains the transgene of interest, a packaging plasmid, and an envelope plasmid. After co-transfection, the packaging cell line is allowed to incubate for a couple of days during which time the LVV particles are produced and accumulating in the culture supernatant. The supernatant containing the recombinant LVV is then harvested and, following several concentration steps, the LVV particles are ready to be used for introducing the desired genetic content into the mammalian target cells.

The scale of this effort is highly dependent on the amount of LVV produced by the packaging cell line (i.e., the resulting LVV titer in the culture supernatant). If only a low LVV titer is achieved, more flasks of the packaging cell line need to be cultured and transfected so that there is more LVV containing supernatant to be concentrated. In contrast, high LVV titer allows transfection of fewer packaging cells minimization of concentration steps. In a recent publication, Hewinson et al. sought to optimize the LVV production protocol, specifically focusing on the initial step of co-transfecting the packaging cell line.

The authors found that using FuGENE 6® Transfection Reagent for the initial co-transfection step resulted in approximately 20-fold increase in LVV titer compared to the more standard CaPO4 transfectionmethod and more than 7-fold increase compared to a protocol using Superfect Transfection Reagent. The authors also compared the efficiency of the LVV particles produced with either the FuGENE® 6 or CaPO4 method in transducing 1-week-old primary neuronal cultures with a fluorescent reporter gene. Interestingly, LVV produced using the FuGENE 6® protocol resulted in higher efficiency transduction of the neurons compared to the LVV produced with the CaPO4 protocol. Both the percentage of total cells transduced and intensity of the fluorescent transgene were significantly higher when using LVV created by transfecting packaging cells with FuGENE 6® reagent.

For laboratories using LVV-based methods, optimizing the initial co-transfection of the packaging cell line could significantly improve the overall efficiency of the LVV production process. Improving this initial step can allow both the cell packaging and concentration steps to be dramatically scaled back, saving both time and resources. In addition, the LVV produced may be more effective in transducing the target cells creating better results in the endpoint assay.

Here is the paper detailing the optimized protocol for using FuGENE® 6 reagent to generate LVV: Hewinson J. (2013) et al., Methods Mol Bio 998, 65–75. http://www.ncbi.nlm.nih.gov/pubmed/23529421