This is part 3 of a three-part series on FFPE sample processing. Part 1 (link) Part 2 (link)

I would like to automate FFPE processing, but I am worried about sample cross contamination, how can I minimize my risks?

As a gold standard for oncology research, hundreds of millions of FFPE samples are collected and banked worldwide. These samples provide a rich source of data for identification of biomarkers in the search for early detection assays for cancer as well as diagnostics that could help direct treatment decisions and monitor treatment.

With the increased interest and utility of these samples, comes a desire to process more samples, which can stress resources in molecular labs.

When processing FFPE samples, many steps are an inherently manual and may not seem easily automated. Paraffin blocks and samples all require some degree of manual intervention to mount, section and then prepare samples for processing for DNA or RNA. Automation of laboratory processes can range from small, benchtop built-for-purpose sample extractors like the Maxwell® RSC to larger instruments capable of processing one or more 96-well plates of samples at a time.

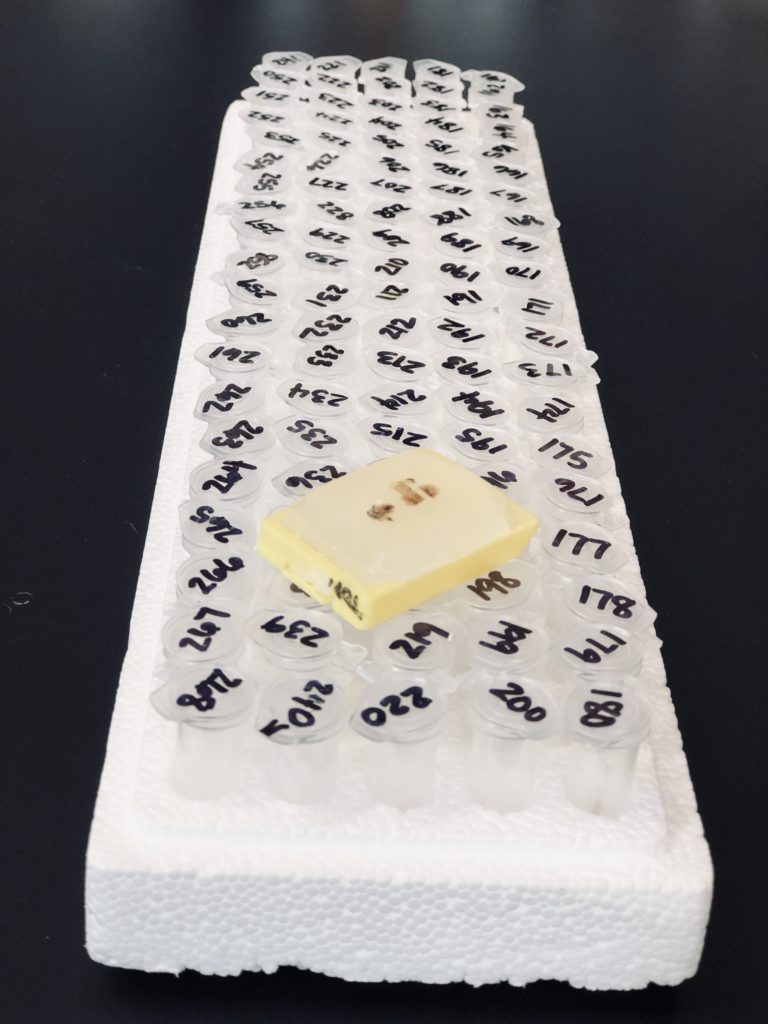

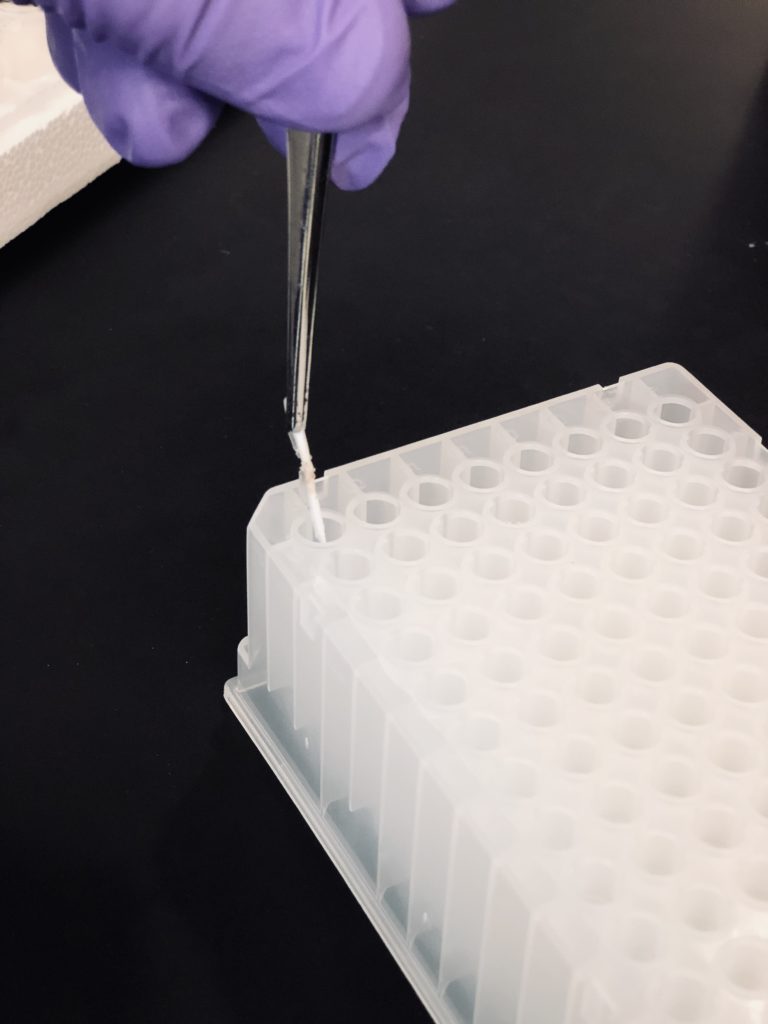

One key concern with automation of sample extraction is the risk of sample mix up or cross-contamination. When working with single sections or scaping material from slides, attempting transfer to a 96-well plate increases the risk of sample contamination or placement errors. A simple approach that Promega has taken for automation of FFPE samples is to begin automated processing by placing FFPE material into individual tubes for preprocessing. Once the sample is in a tube the remainder of preprocessing steps can be automated on our Maxprep™ liquid handler, processed using a third-party automation platform or performed manually. Temperature blocks can be defined as labware on liquid handlers allowing instrumentation to assemble reactions, incubate samples and transfer samples to plates or cartridges for DNA or RNA purification, eliminating manual manipulations once the sample is placed into the initial tube. The Maxprep instrument uses two independent methods. For the first method the tubes with FFPE sections in them are placed on the Maxprep, and the instrument assembles the lysis reaction. The tubes then are then removed from the Maxprep instrument for incubation. After incubation is complete, tubes are returned to the Maxprep instrument. for the second method that includes RNase or DNase treatment (for DNA FFPE and RNA FFPE, no treatment for FFPE Plus DNA), prepares cartridges with plungers, adds elution buffer to elution tubes and transfers lysed samples to well 1 of the cartridge.

Beginning sample extraction with FFPE pieces in individual tubes significantly reduces the risk of accidental sample contamination. Once the samples are transferred to the instrument, the risk of contamination decreases significantly. Promega extensively tests automated methods for sample/sample contamination. The Maxwell® instruments are specially designed to have a low risk of cross contamination.

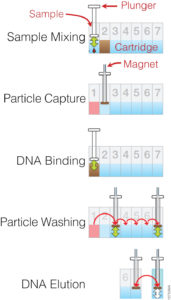

Samples are processed using magnetic particles; the sample is added into a binding buffer, and the instrument uses magnets to move the particles (and bound nucleic acid) from well to well. Ultimately sample is eluted into a small tube at the front of the instrument. Throughout this process, the samples are processed in a linear fashion so that no sample will cross over other sample wells, essentially eliminating the change of cross contamination during instrument processing.

When processing samples on large liquid handlers, the samples often remain in a 96-well plate, and the instrument will add and remove liquids from the well using 8 channel pipettors or 96 well heads. In this type of processing, the pipetting arms pass across the surface of other samples, so care must be taken in programming instrumentation to prevent inadvertent sample contamination.

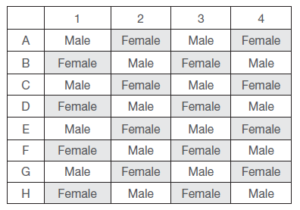

Ultimately a final method should be tested to determine that sample integrity in maintained. This is often accomplished by performing a checkerboard experiment alternating male and female samples. Eluates are then tested by qPCR analysis of a male-specific target to determine that there is no cross-contamination between samples.

Promega supports liquid handlers and particle movers. If you have an instrument you would like to use for FFPE extraction, Promega scientists can offer extensive assistance in programming and training. To learn how Promega can assist you in automating nucleic acid extraction protocols visit our automation resource at: https://www.promega.com/products/nucleic-acid-extraction/genomic-dna/maxwell-ht-nucleic-acid-purification/?cs=y

Want to know more about how the Maxwell® RSC can give you the freedom to focus on the work that interests you the most? To learn more, click here.